Menu

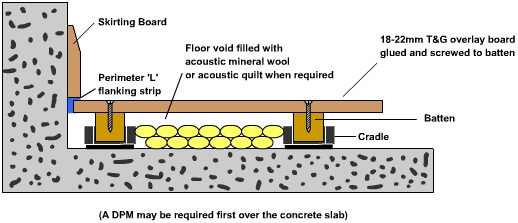

Acoustic Cradle Flooring System that reduces the transmission of impact and airborne sound through concrete floors. This is achieved by acoustically isolating the top floor surface from the structural floor.

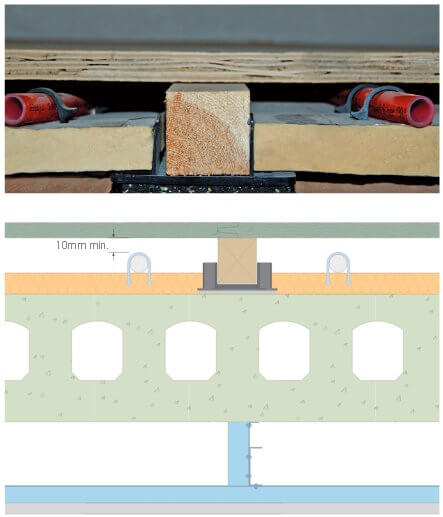

The Acoustic Cradle consists of a high performance, recycled, high density, 10mm resilient Isolate C rubber base which, unlike similar products, has excellent static deflection properties as well as the advantage of long life, since it will not degenerate over time like foam-backed products, thus preserving performance standards.

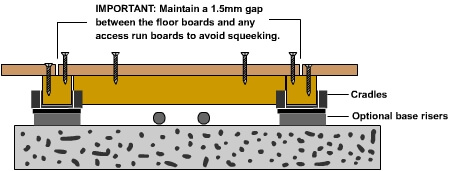

Using the Acoustic Cradle System with our 2mm, 3mm and 5mm Acoustic Cradle ‘Packers’ allows level floors to be constructed even when the base concrete floor slab is uneven.

The packers are simply inserted into the cradle underneath the battens.

When increased finished floor heights are required to cater for specific design criteria, deep services or very uneven sub-bases, we can supply an interlocking 15mm or 30mm deep cradle base packer which simply slots in underneath the main cradle.

The cradle base packers may be used in multiples to achieve the desired finished floor height.

When installed as part of a complete party floor construction this system enables a concrete floor to meet the sound transmission standards of Approved Document E 2003 (amended 2004).

Treated floors meets New Robust Detail FFT2, typically within Robust Detail EFC-1, EFS-1, EFC-2 and EFC-7.

Product Data |

|

| Overall cradle size: | 96mm diameter x 43mm |

| Height of baseplate: | 8mm |

| Resilient layer: | Isopoli-HD |

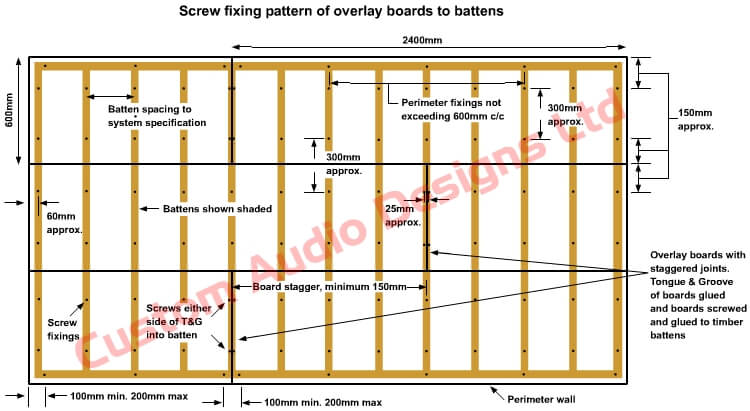

Access runs may be formed as required by the introduction of removable boards cut to suit. Ensure that the access run boards and adjoining floor boards are supported by the introduction of cross-battens located within the cradles. Additional battens and cradles may be required to suit the position of the access run.

1-3 working days delivery for in stock items (unless stated otherwise on the product page); may be longer for rural postcodes. For more information click here